I was tempted to keep this photo to myself, but decided I may as well put it out there, especially since fellow small business owners will relate: That first check was cause for celebration!

In the middle of the holidays, I realized that another important occasion had crept up on me: the 10th anniversary of Dark Horse Woodworks. Our first day of business was December 28, 2007, and like many of my fellow cabinet makers, our first place of business was my garage.

When you go out on an entrepreneurial limb, it’s both exciting and terrifying. Taking my sideline full-time was a risk and a leap of faith, and back then, I wouldn’t have dared think ahead to whether the company would still be around a decade later.

I’m very happy to be one of the people whose leap of faith paid off; big anniversaries like this one are nice because they make you stop long enough to look back and take stock.

A character-building experience

There’s no question that running your own business brings plenty of headaches, trial-and-error learning and moments of sheer panic. Even when your venture becomes a success, you go through times when you feel nostalgia for the days when your business was smaller and you had less on your plate.

Some days, success means keeping your sense of humor and perspective intact long enough to avoid crossing that dreaded boundary where the thing you love becomes the thing you dread.

Thankfully, along with all of the challenging times and learning curves, Dark Horse has also seen more than our fair share of high points – positive changes in the business itself, exciting honors and gratifying feedback for our work, and great relationships with peers in the industry.

Bigger space, bigger ideas and a bigger universe

Dark Horse Woodworks’ growing physical footprint may be the most obvious change we’ve seen in the past 10 years. Looking back, the thing that astounds me most is the fact that I built a few kitchens for people in my 400-square-foot garage. Now that I have 6,000 square feet (and wish I had even more), it just seems impossible.

Early garage shop days…

A tight squeeze.

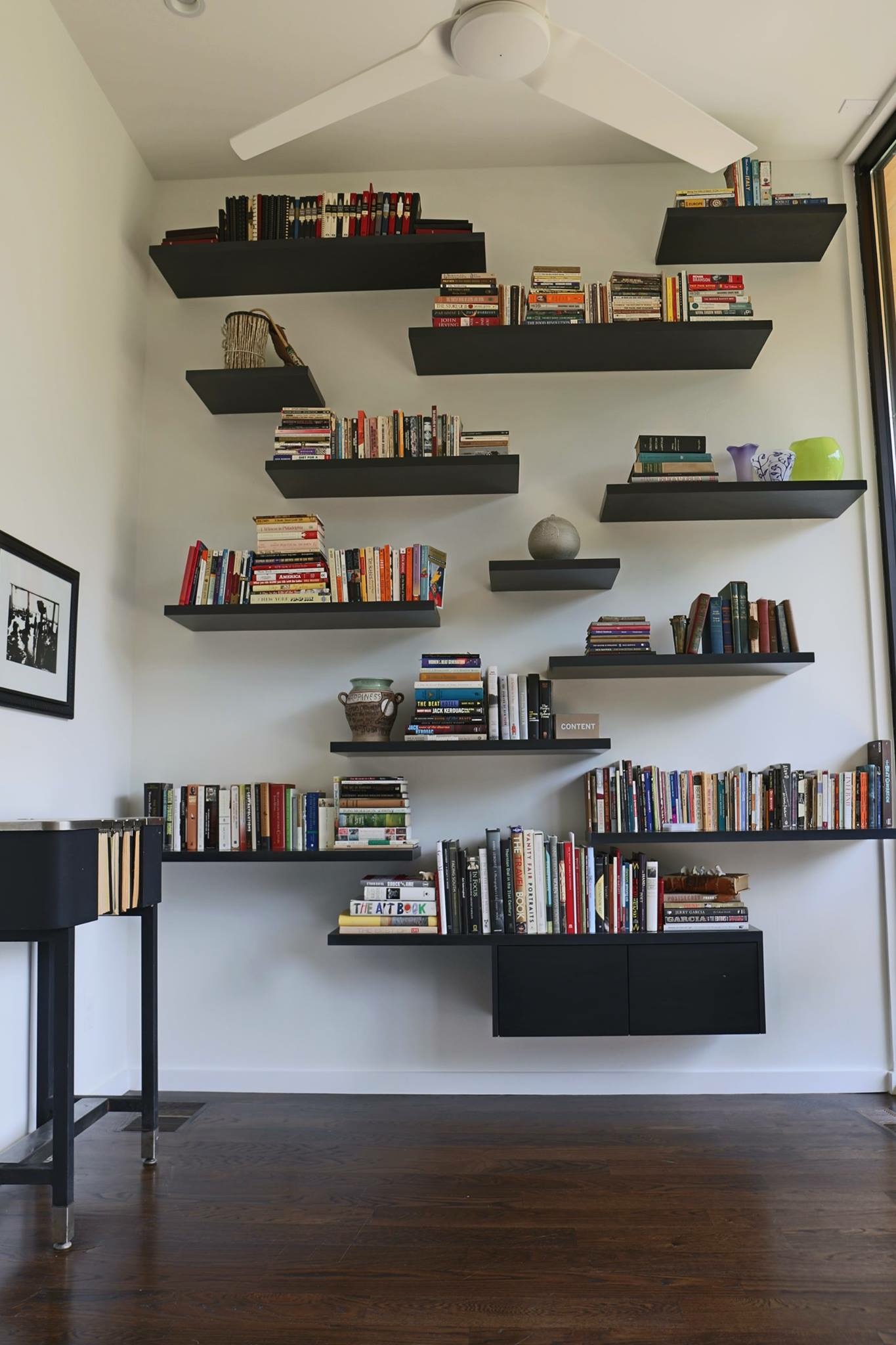

Using every bit of space – vertically and horizontally.

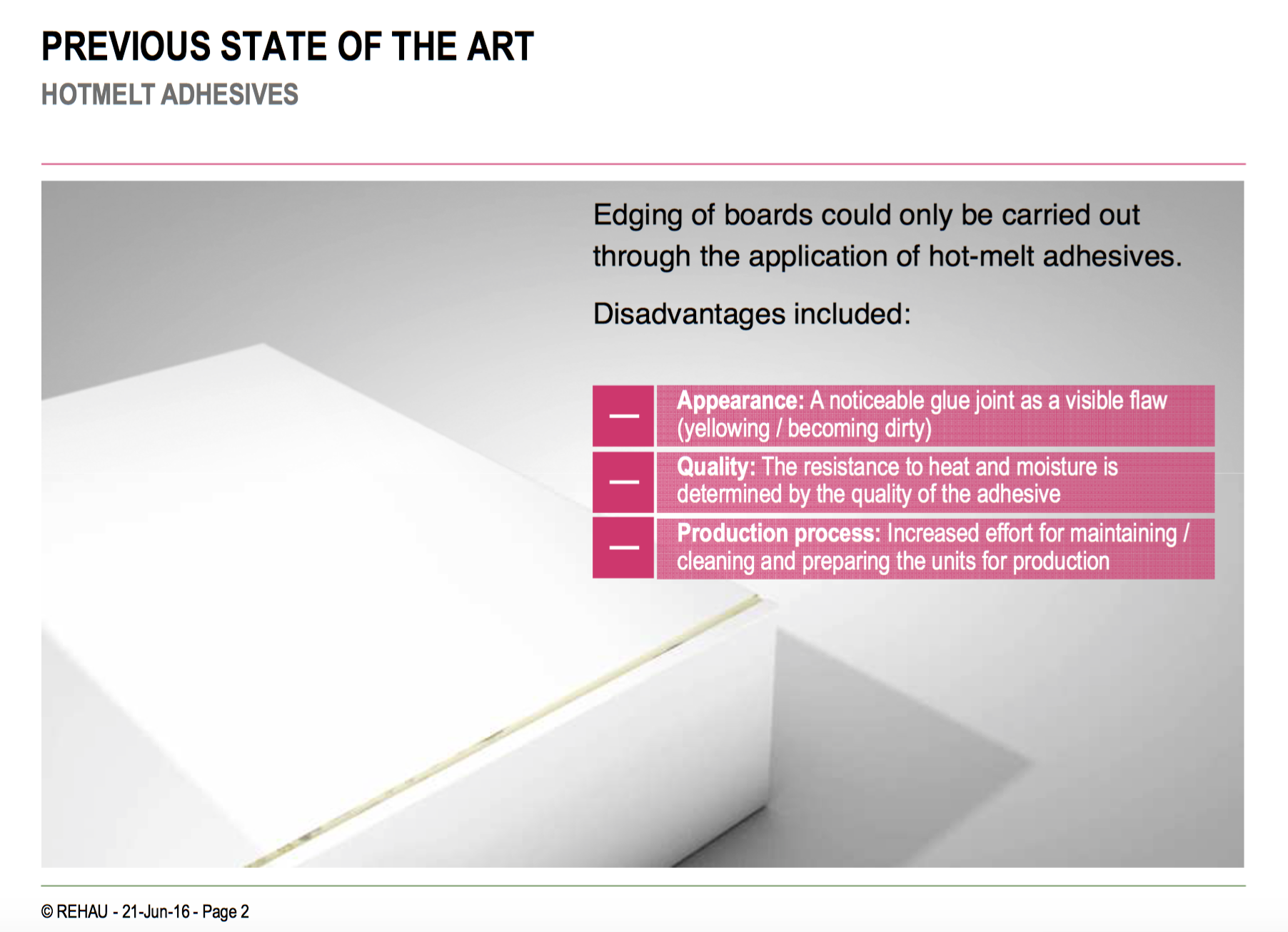

Along with the increase in square footage, we’ve also expanded the technology we have on board, which has enabled us to expand the services and types of cabinetry we can offer. (We’ve written on the blog about our Zero-Edge technology and about the CNC router that we added just this past year.)

We also joined the Cabinet Makers Association (CMA), the association for professional cabinet makers and woodworkers in the United States and Canada. This turned out to be a huge decision for us; after all, at 10 years old, Dark Horse is still a newcomer compared to many CMA member shops that have been around for several decades. I always learn a lot thanks to the generosity of more experienced CMA members.

On top of the relationships and resources, we’ve also been recognized with multiple CMA “Wood Diamond” awards every year since we joined; being recognized this way by our peers is important validation that our work is hitting the highest marks.

Accepting one of our 1st-place Wood Diamond awards from CMA president Matt Krig in July 2017

A couple of years ago, I was honored to be elected to the board of the CMA, and I always enjoy being part of the regional events, shop tours and trade show activities. In March, I’ll be doing a presentation at the CMA’s 20th Anniversary conference in Denver, and this summer, I’ll be a CMA speaker at the International Woodworking Fair in Atlanta. It’s a good feeling to have gone from being a novice in the cabinetry/small business world to having learned enough to be able to share some often hard-won lessons with others; starting and building Dark Horse has been a little like getting a 10-year business and entrepreneurship degree.

Teamwork

We would never have made it this far without clients, architects, designers and homebuilders who trusted us to team up with them on their projects.

I have some really great clients who have become great friends since we did their projects, and I’m especially appreciative of the folks who hired Dark Horse back in the early days before we had a track record.

And of course, I could never have made the business a success without the people who have worked for me over the course of our first 10 years; thank you for helping Dark Horse deliver quality and workmanship to each of our clients.

Icing on the cake

We would be bad marketers if we didn’t share the good news when our work gets coverage in the media, so if you follow our blog, you may have already read about some of these things.

But marketing aside, seeing your work in a publication or recognized in the community is pretty thrilling on a personal level, so I wanted to mention those kinds of high points in this anniversary post, too:

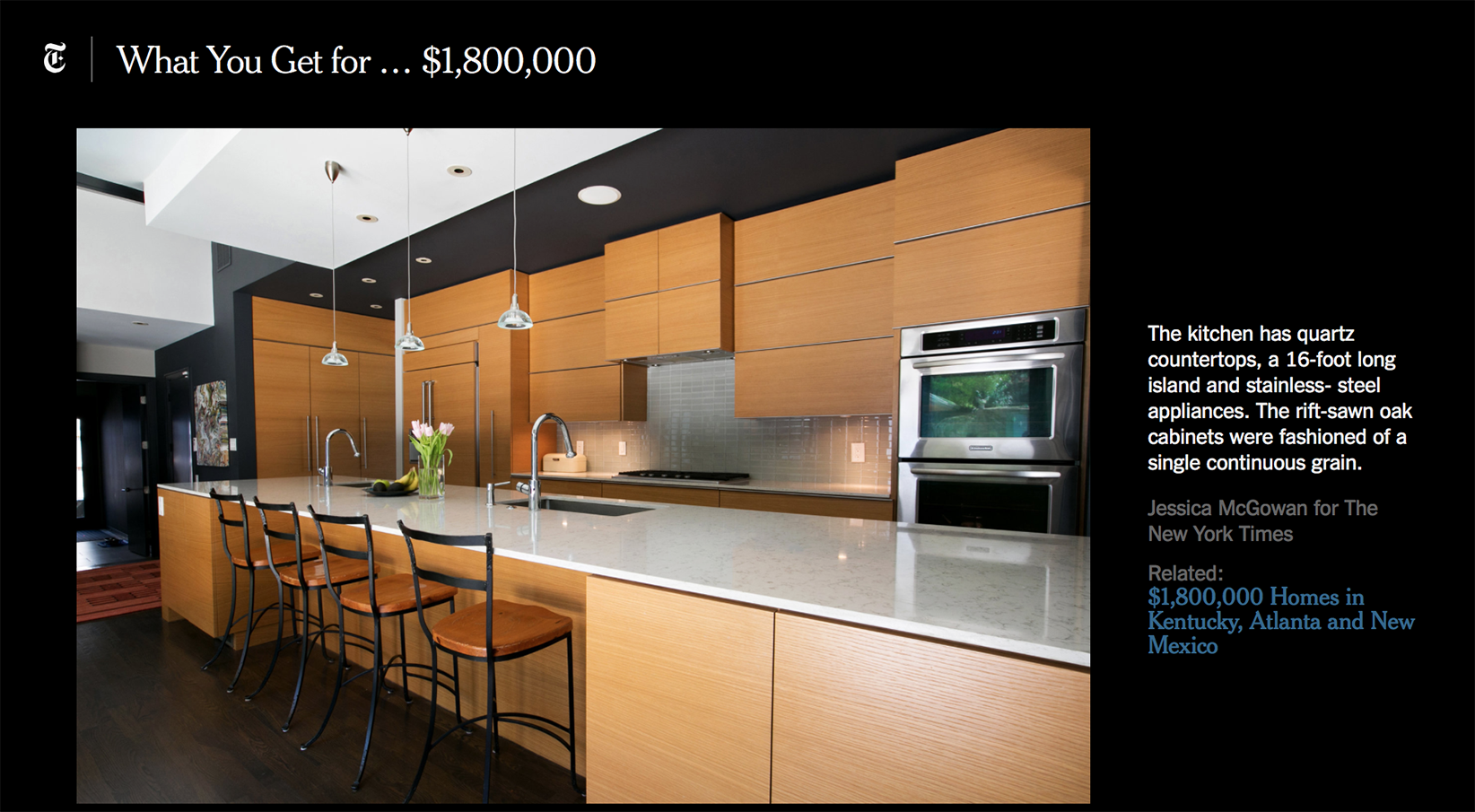

- The Friar Tuck project was featured in a New York Times real estate story.

- The Oakview home was featured in Dwell magazine magazine.

- I was glancing at Dwell’s website one day and found more of our work in several of their online features.

- Curbed Atlanta featured a home with a Dark Horse kitchen (created with Zero-Edge technology) in July.

- Dark Horse was the cover story in the Winter 2017 issue of PROfiles, the CMA magazine.

- The CMA invited us to participate in a video series in 2017 and gave me a chance to talk about how we got started, why I love what I do and some of the technology that is taking Dark Horse into the future. Feel free to check out the interview (it’s a bit over two minutes long).

- Our work has also been included on the highly respected (and popular) Modern Atlanta home tour three times.

Thanks to everyone for your support and cheerleading; I’m looking forward to seeing what our next decade brings.

~ Chris Dehmer

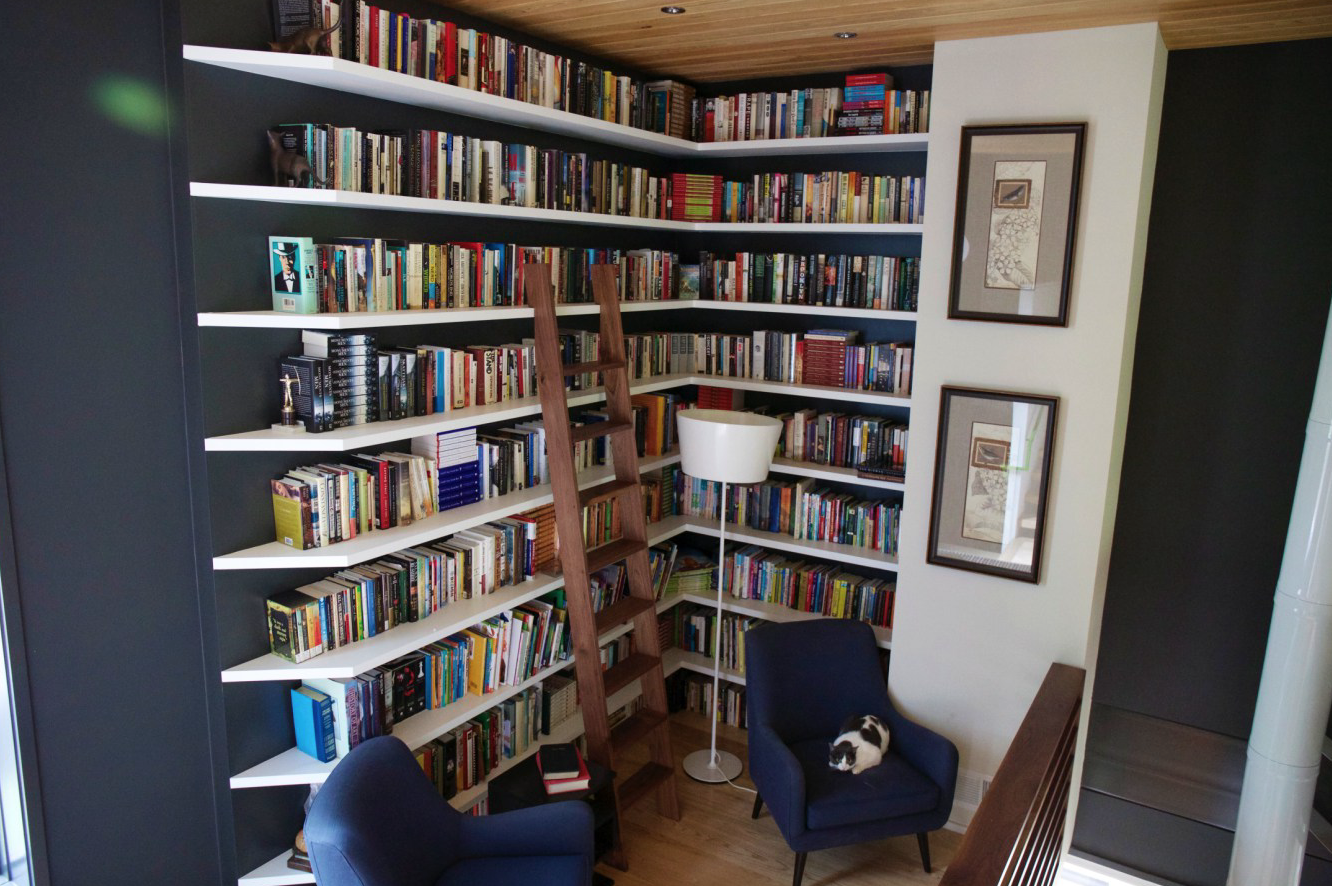

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

At Dark Horse, we’ve always had an Old-World emphasis on craftsmanship, quality and attention to detail.

At Dark Horse, we’ve always had an Old-World emphasis on craftsmanship, quality and attention to detail.

In our relatively short history – Dark Horse was created in 2007 – we’ve had a lot of good news come down the pike.

In our relatively short history – Dark Horse was created in 2007 – we’ve had a lot of good news come down the pike.

We’re happy to share the news that Dark Horse Woodworks’ Chris Dehmer has been elected to the board of the

We’re happy to share the news that Dark Horse Woodworks’ Chris Dehmer has been elected to the board of the