In this modern version, I’m the cobbler, and it’s way past time for me to build a new kitchen at my house.

Our first kitchen reno – pre-Dark Horse

I’m pretty sure it’s impossible to build dream kitchens for clients year after year and not want to create your version of the ideal kitchen.

Long ago, about six years before chucking my day job and starting Dark Horse, I renovated our kitchen on my own. When we’d moved into our Craftsman-style house, the kitchen was tiny, maybe 10×10. It had a sink and a refrigerator, and that was it. The original giant cast iron sink was rusted and not very practical. The metal cabinets were not deep enough to hold modern dinner plates, and there was no stove or oven.

When we first bought our house, this was the state of affairs in the kitchen.

And another view; this kitchen is a cabinetmaker’s nightmare.

The renovation I did as an amateur with some solid skills was fine – and it was certainly a huge step up from what we started with. The style we went with then was traditional, and the kitchen has served us well.

But about three years ago, I reached the point where I had to do something with all of that inspiration I’d been getting from my Dark Horse work. While there was nothing wrong with our kitchen, it was not what I’d call “awesome” – and I wanted to come home to a truly awesome kitchen.

My wife and I were on the same page, and the decision was made.

Getting started

There’s no doubt that there are advantages to being a professional when you’re doing a personal kitchen reno project. But I’ve learned firsthand that there are some hurdles you can’t escape whether you’re an amateur or a pro, and other things that become more complex because you do this stuff for a living.

For instance, I quickly figured out that when the goal is agreeing on a design and making all the other decisions that have to be made, having professional expertise in the mix can complicate matters instead of speeding them along.

Most couples setting out on a renovation are starting from the same place, after all, learning as they go.

The unique challenge for my wife and me was the fact that we brought two very different perspectives and sets of experience to the table. Because I do this for a living, I have what is probably an excruciating amount of knowledge about everything that’s involved. On top of that, building kitchens for a living also means that I have strong preferences.

To sum up what I mean, picture this not-so-imaginary scene: My wife rolls her eyes as I explain why we must have XYZ feature/material/hardware in the new kitchen. Minutes later, I throw my hands up because she just doesn’t appreciate the great wisdom I’m bringing to the process. Repeat scene – many times.

Beyond the difference in perspectives, doing your own renovation also makes you appreciate the ease of working with clients on a kitchen that isn’t yours.

I have many conversations with clients about what their dream kitchens will look like, and I now recognize what a breeze this part of the process is for me. During the planning and design step, I get to lay out the options, explain the basics and then exit the process. The clients go away and hash things out, and we meet again to finalize everything.

When it’s your kitchen, you can’t step away from the process and let other people make the decisions. You have the same challenge as all of your clients who are doing a renovation with a partner: You have to work through it all with the other person, make a case for your (strong) preferences and end up as close to mutual satisfaction and civility as possible.

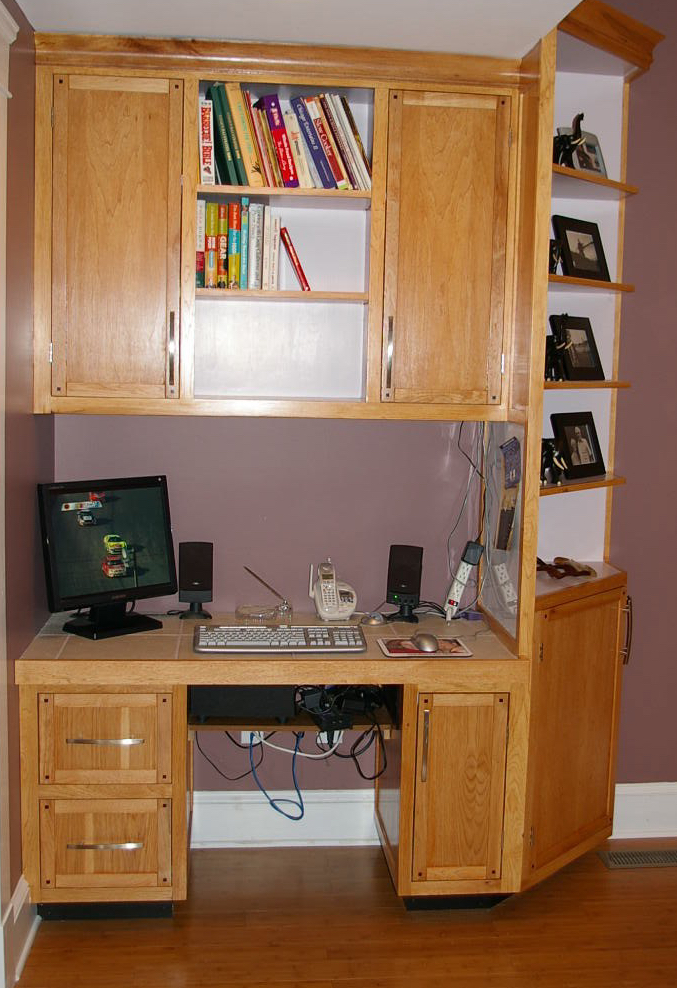

Another shot of the first kitchen I installed; it’s all gone now.

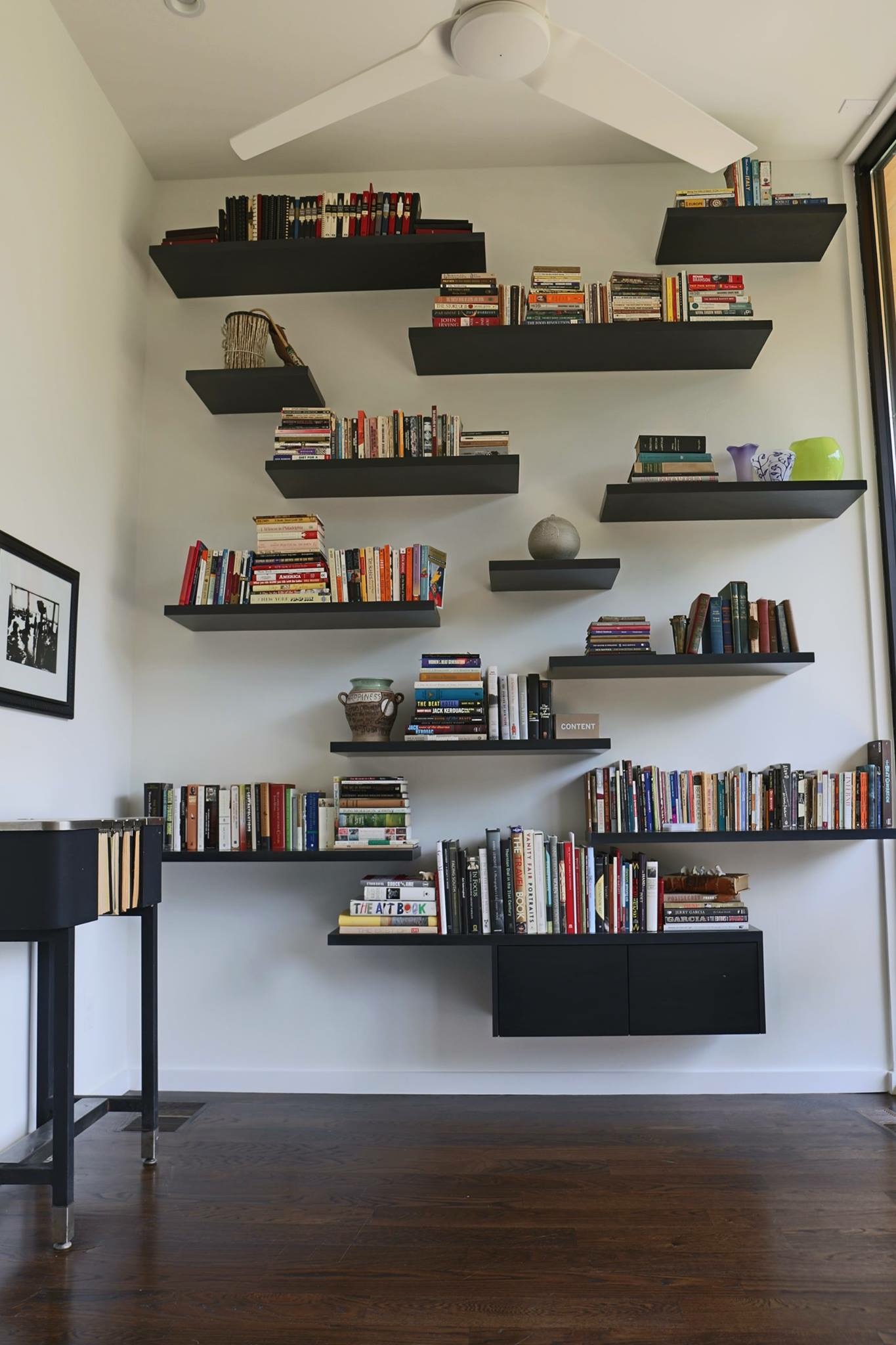

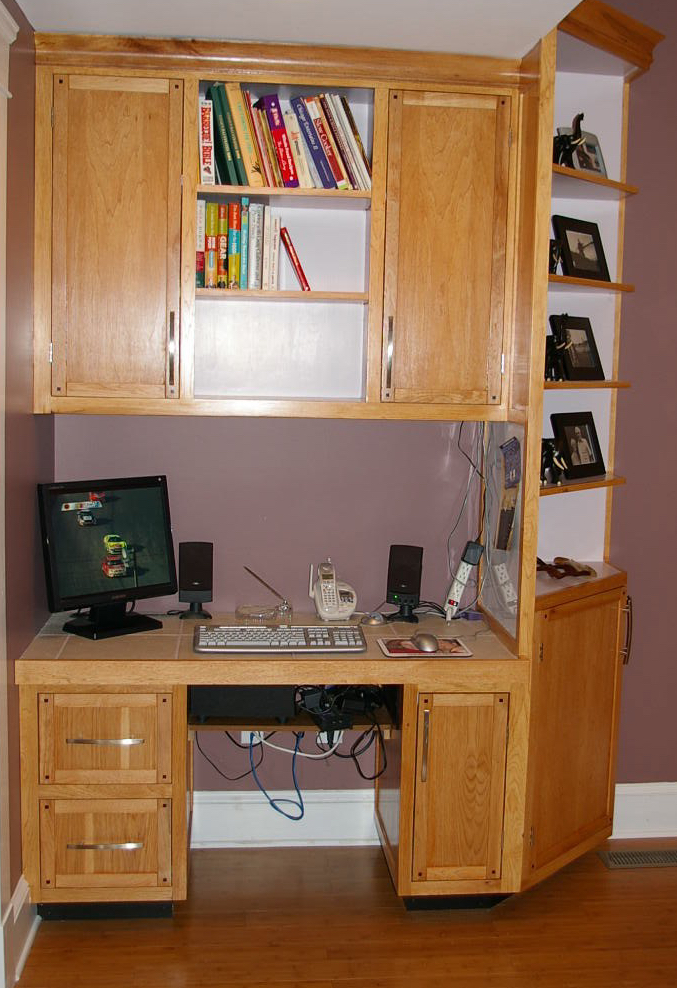

Desk area included in our original reno kitchen

Finding common ground

So how did we get through the decision-making phase?

My wife had been looking at a website called Houzz since we first started talking about the project three years ago.

In case you’re not familiar with Houzz, the short version is that it’s a website filled with home design ideas, photos of real-world, finished projects, vendor pages and a lot more. Dark Horse and pretty much any other company involved in building or renovating homes have a presence on Houzz because so many homeowners go there to search for ideas. Houzz turned out to be the main driver for my wife to figure out what she liked.

My past projects were a big source of inspiration for me, of course, and I knew from the start that I wanted to move away from the traditional look of our current kitchen. I liked some aspects of the modern kitchens that have become our specialty at Dark Horse.

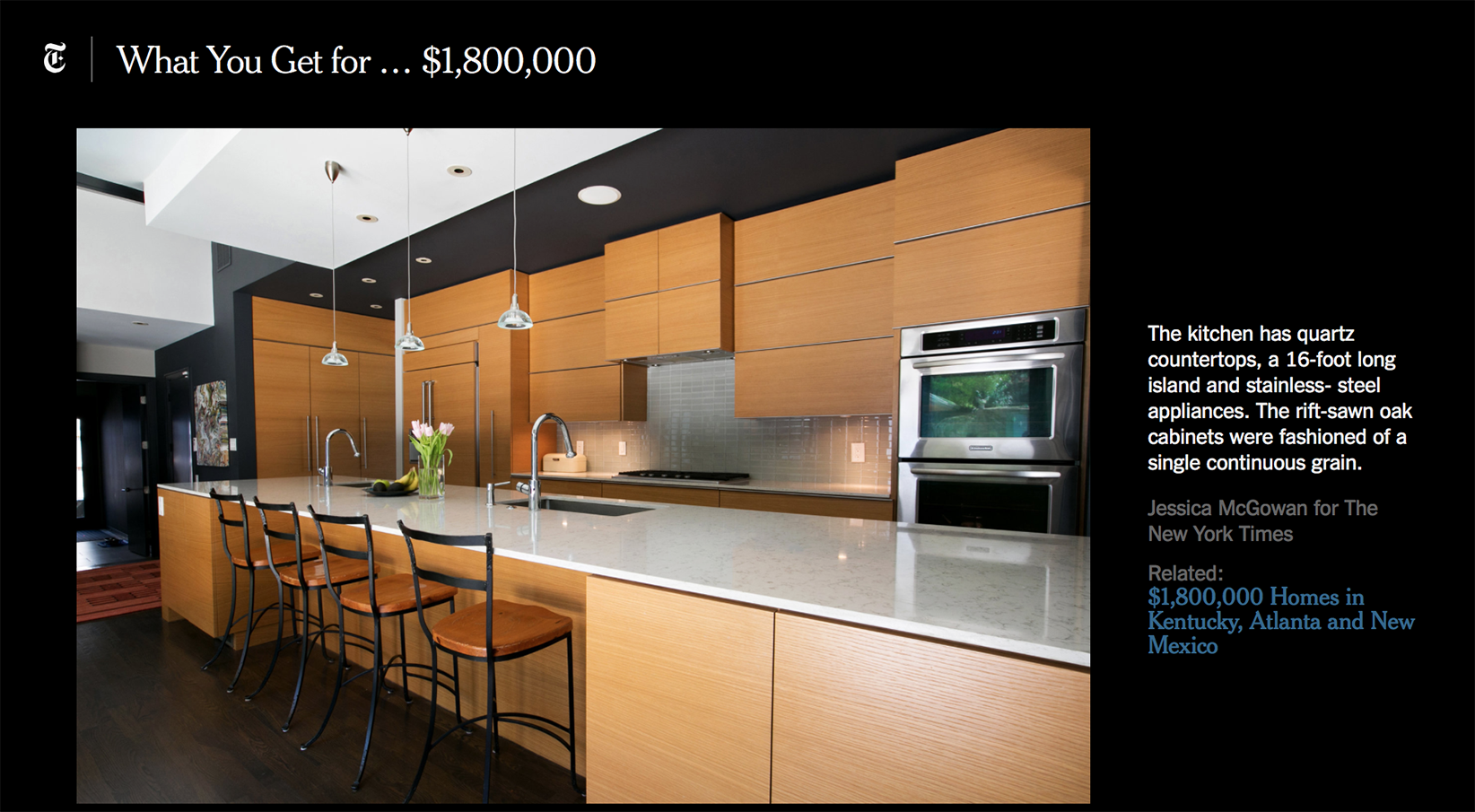

At some point along the way, I spotted a kitchen I really liked in my wife’s saved projects on Houzz. I had never seen a style quite like it, and I’m sure that’s what caught my attention. By the time this kitchen entered the picture, we were on about version 6 of our project design attempts; the fact that we both liked this one was big, and we knew we needed to run with it.

There were still compromises to be made along the way, of course – for instance, my wife wanted painted cabinets, and I preferred wood grain. In this case, I decided not to push my preference since the overall design was something I liked.

Chance encounters

On top of the challenge of getting on the same design page, we also experienced another common renovation struggle: Getting to the starting line.

Building other people’s cabinetry for many hours a day can certainly take a toll on your personal renovation plans, and even the goal we’d picked as an incentive ended up being a convenient excuse to delay the project. When we’d decided to go forward with the reno three years ago, our goal was to have it completed before the Dark Horse holiday party that we host in early December every year.

But for the next couple of years, when work projects and personal obligations began to stack up in the months ahead of December, we’d throw in the towel. “Well,” one of us would say, “there’s no way we can get it done before the party now, so we might as well wait.”

In the end, it was a chance encounter that threw the switch on the project at last.

In January 2016, with the latest holiday party behind us and the renovation still not scheduled, I headed to a big industry show in Orlando. While I was checking out new hardware and other products for Dark Horse, I stumbled across some cool retro appliances, and they gave me a new shot of inspiration.

I came home and sent an email to a design team I know and asked them if what I had in mind was up their alley. They sent back an enthusiastic “yes,” and by the end of January, I had sent them a list of the appliances and other things we liked.

Full-steam ahead

By the end of February, the designers had sent us options for finishes, floor tiles, walls, backsplashes, etc.

The style we landed on doesn’t fit neatly into any of the usual categories, so maybe “eclectic” is the best way to describe it. There are modern elements, such as clean lines and minimal door hardware. The raised panels on the doors (kind of a reverse Shaker) give a nod to the Craftsman style of the house, and we added some retro touches via the appliances, tile floor, backsplash and reeded glass doors.

Once we hashed out the design particulars, the project fell into a good rhythm.

In March, we made final decisions on appliances, and by Memorial Day, I had begun building out the cabinetry. Around the first of August, the cabinets were done, and I decided to start demo the week of Labor Day. One of our dogs is petrified by loud noises, and we decided it would be better to have him out of the house; my wife and the dogs headed out of town to join family for a long-planned vacation, and I got ready to dismantle that kitchen I had labored over all those years before.

On HGTV shows, everything I’ve just described takes place in a span of days, not years, and “Demo Day” is a pretty exciting highlight for everyone, with homeowners and TV hosts alike bashing walls and ripping cabinets apart.

In order to keep some suspense and excitement going in my reno story, I’ll wrap up Chapter 1 (“before”) here and begin Chapter 2 (“during”) with the thrills of Demo Day; be sure to tune back in to find out what a Demo Day is like in the real world!

SaveSaveSaveSave

SaveSave

Dark Horse Woodworks’ Chris Dehmer has been elected president of the Board of Directors of the Cabinet Makers Association (CMA), the industry group for professional cabinet makers and woodworkers in the United States and Canada.

Dark Horse Woodworks’ Chris Dehmer has been elected president of the Board of Directors of the Cabinet Makers Association (CMA), the industry group for professional cabinet makers and woodworkers in the United States and Canada.

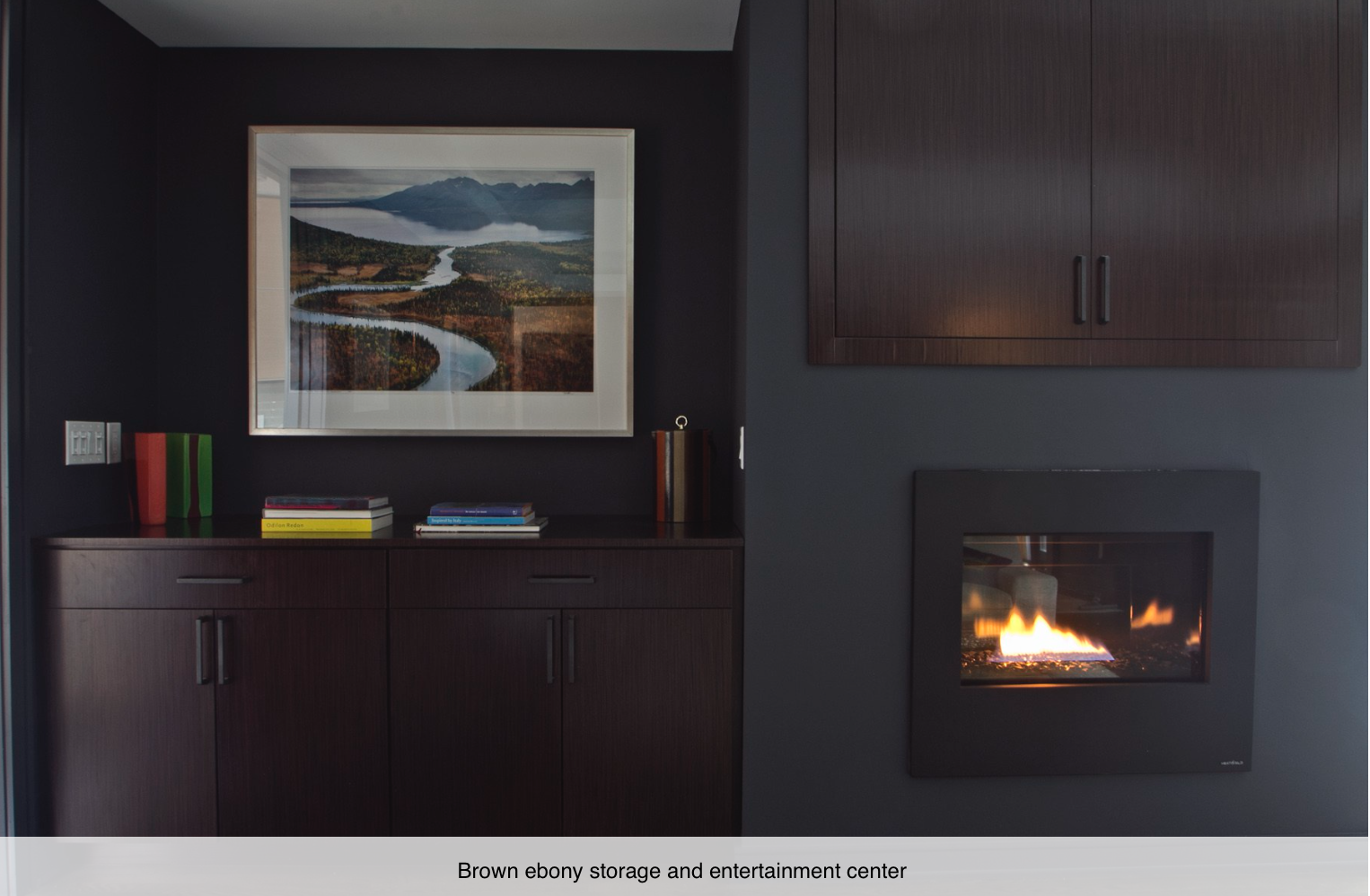

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

In our relatively short history – Dark Horse was created in 2007 – we’ve had a lot of good news come down the pike.

In our relatively short history – Dark Horse was created in 2007 – we’ve had a lot of good news come down the pike.