The International Woodworkers Fair (IWF) is coming to Atlanta in August, and Dark Horse is pleased to be a featured stop on a pre-IWF shop tour organized by the Cabinet Makers Association (CMA).

The International Woodworkers Fair (IWF) is coming to Atlanta in August, and Dark Horse is pleased to be a featured stop on a pre-IWF shop tour organized by the Cabinet Makers Association (CMA).

The all-day tour on Tuesday, August 21, will include stops at several Atlanta-area shops – Atlanta Cabinet Shop and Custom Creative Furniture are participating along with Dark Horse. (CNC Factory is sponsoring the event.)

“My experience being on the CMA board inspired me to participate,” says Dark Horse owner Chris Dehmer. “It’s great to be part of a group that is so generous with its time and so willing to share its experience. I’m inviting people to come on the CMA tour and tell me what we’re doing wrong!”

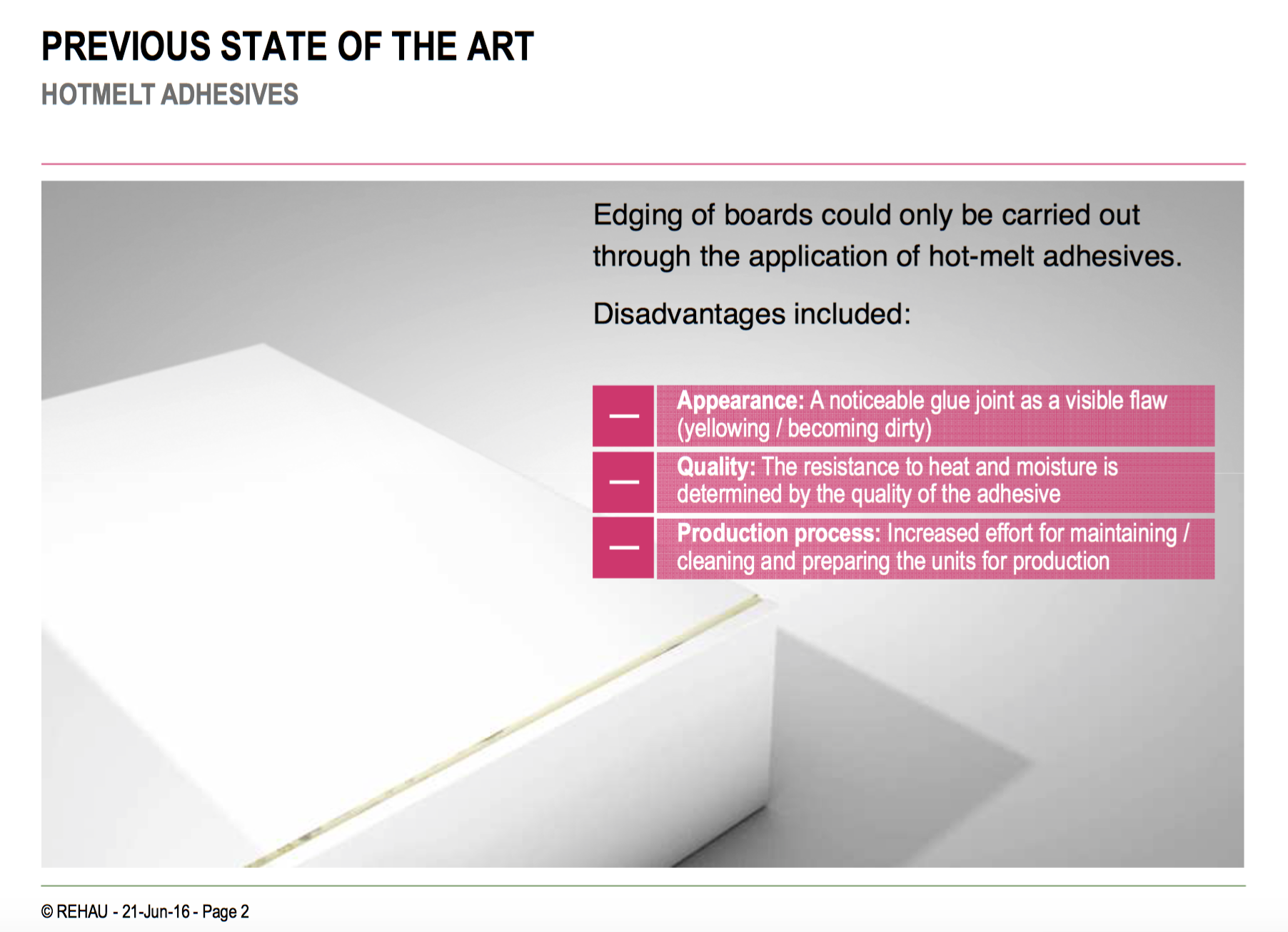

Dark Horse has invested in technology to optimize its capabilities and work flow as well as the quality of its products. Tour participants will get a chance to see how a small shop makes use of innovations such as Zero Edge technology and a CNC router.

The shop tour event gets rolling early with a 7:30 am breakfast at the Embassy Suites (Centennial Olympic Park) and continues throughout the day.

Registration includes group transportation as well breakfast, lunch and an evening reception.

The shop tour cost is $55 for current CMA members and $75 for non-members. Student/Instructor members can participate at no charge, while non-member students/instructors will pay a discounted rate of $25.

You can register via the CMA website.

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.