At Dark Horse, we’ve always had an Old-World emphasis on craftsmanship, quality and attention to detail.

At Dark Horse, we’ve always had an Old-World emphasis on craftsmanship, quality and attention to detail.

But we don’t believe that having Old-World values means you can’t embrace ways of working that are very much New-World. In our 10 years in business, Dark Horse has experienced first-hand the benefits that great technology and an open mind can bring to our process and to the final product we deliver to clients.

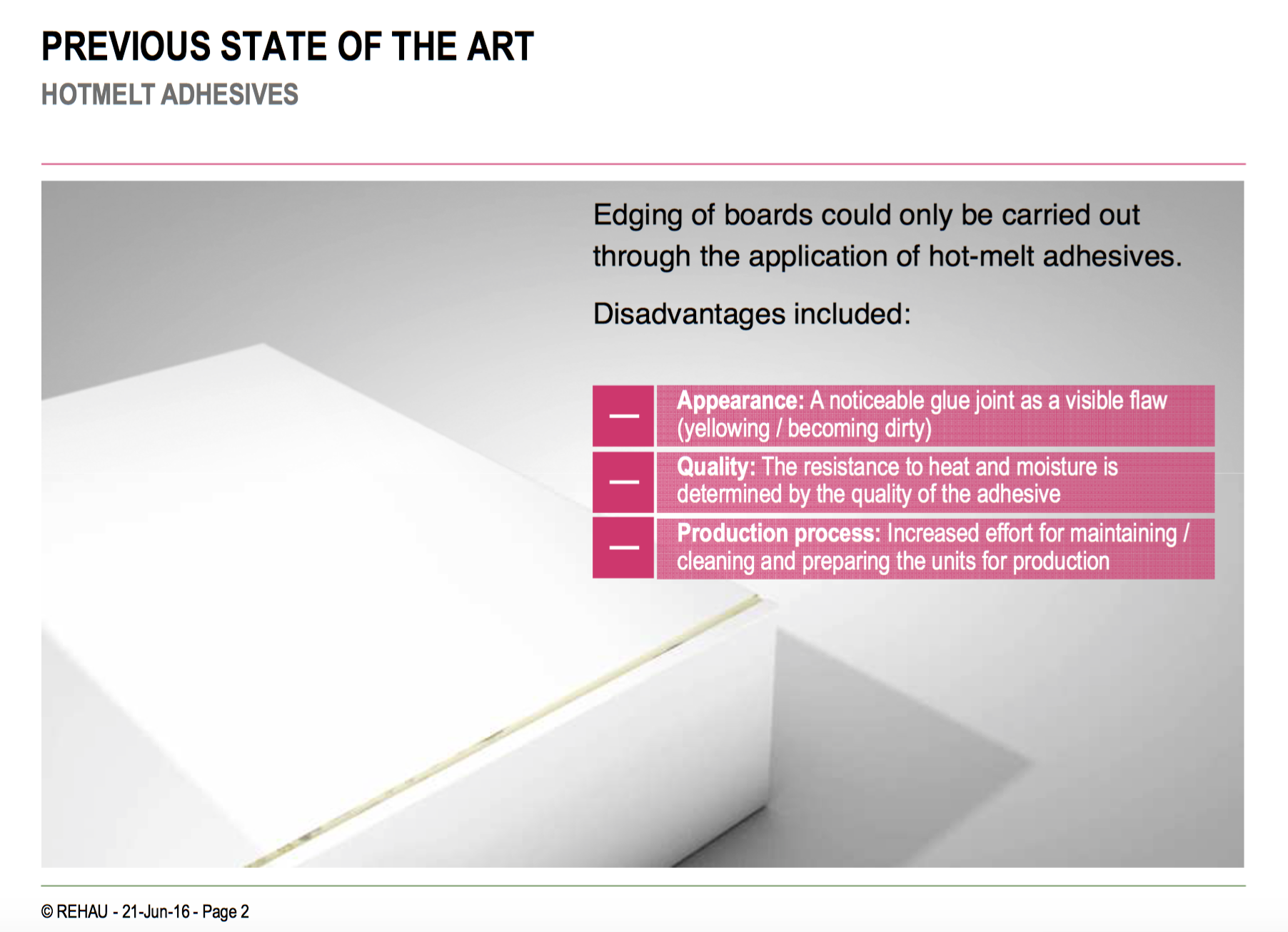

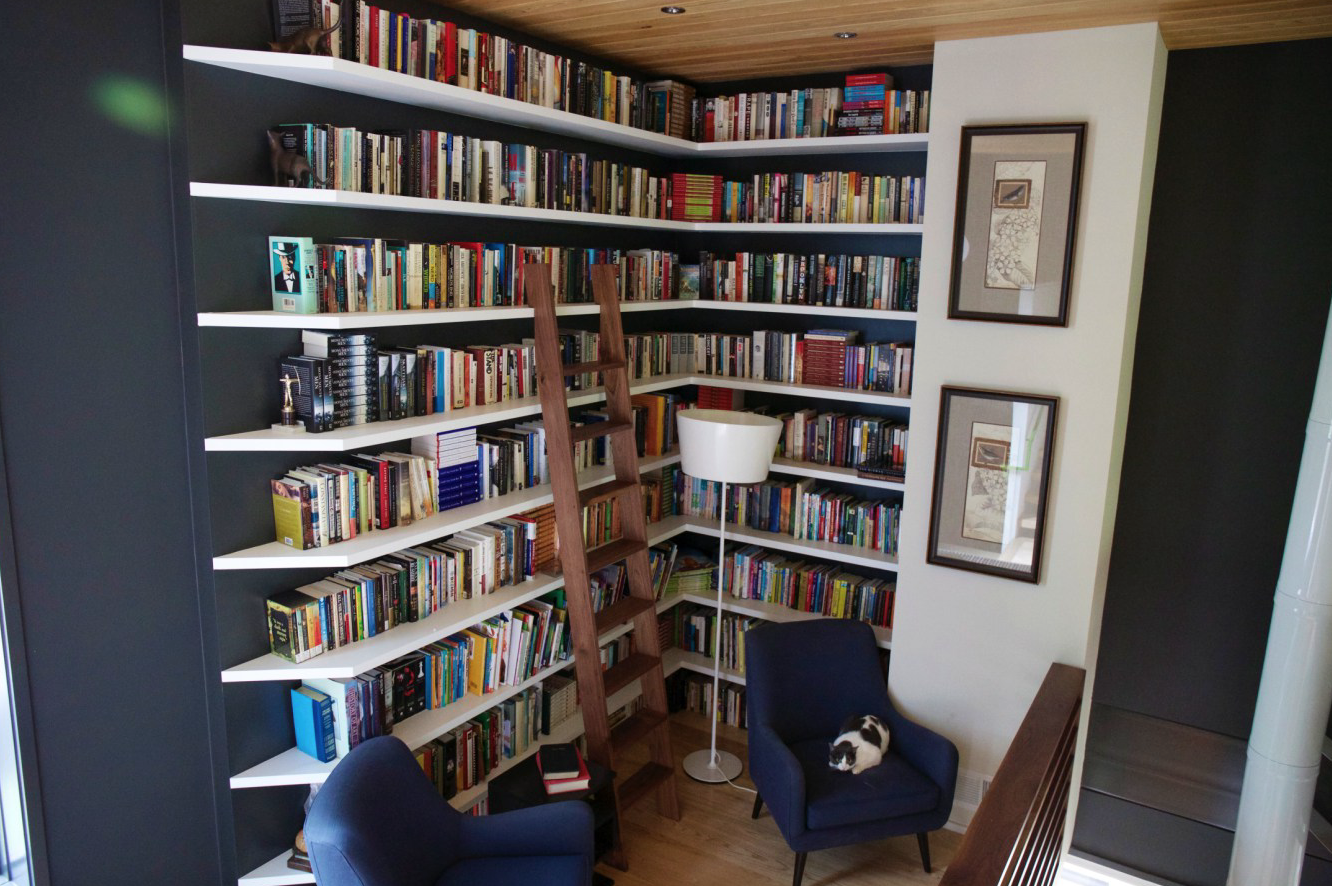

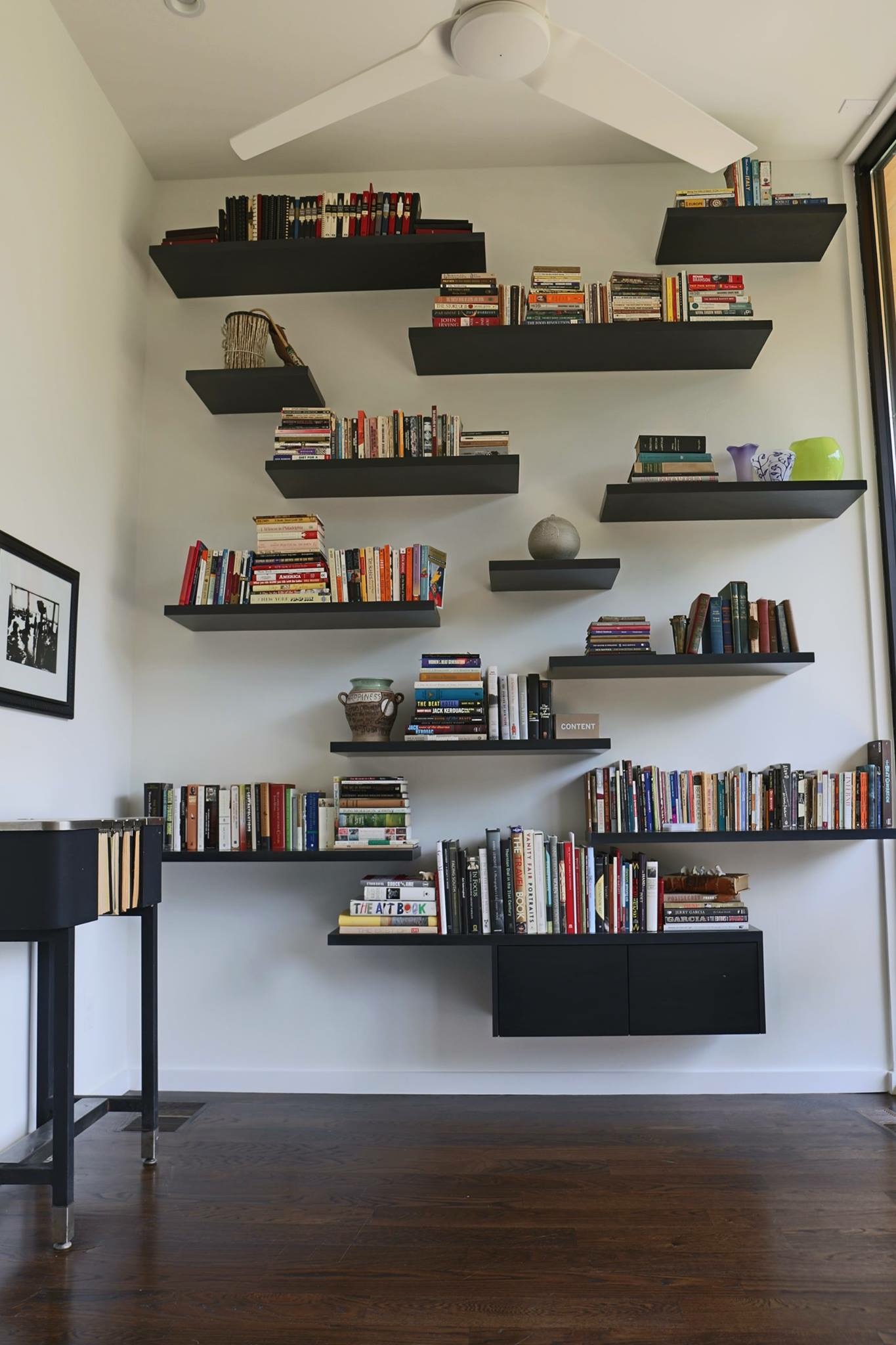

Awhile back, we shared photos of Wildwood, our first big high-gloss kitchen cabinetry project that was made possible by the Zero Edge technology we invested in last year.

In March, we had another red-letter day on the technology front: Our very own, shiny new CNC router was delivered.

For those who aren’t in our line of work, it may be pretty challenging to convey just how exciting this was, but we’ll give it a try.

So what is a CNC router?

Let’s start with CNC.

We found a pretty straightforward definition online at technologystudent.com:

CNC [stands for] Computer Numerical Control. This means a computer converts the design produced by Computer Aided Design software (CAD), into numbers. The numbers can be considered to be the coordinates of a graph, and they control the movement of the cutter. In this way, the computer controls the cutting and shaping of the material.

Dark Horse will now be using a method sometimes called “screen to machine” to cut the parts for our custom cabinets in-house.

We draw the components on a computer screen with design software, which then sends code to the CNC router. The machine takes that data and cuts all of our cabinet parts so that they come off the machine ready to go — all holes for hardware are drilled, etc.

Thanks to the interaction of the software and the machine, the router grabs the right tool for the task at hand, then changes to another tool automatically when needed.

With screen-to-machine production, the possibility of injury is greatly reduced (fingers are on a keyboard, not next to spinning blades), and the accuracy is ridiculously good (1/1000 inch).

To see the router in action, check out this time-lapse video of our new machine cutting trolley signs to be sold by South Atlantans for Neighborhood Development (SAND).

A logistics win

There are many intricacies that this process makes possible – including generating a single file with a unique name for each sheet of material that is going to be cut and a label for each piece.

Basically, once the design is approved, files are sent to our network that tell the machine every operation that is required for the parts on each sheet; in addition, a printout is made for each sheet that has a barcode at the bottom corresponding to the file name of the sheet to be cut.

The operator scans the barcode at the bottom of the page, the machine loads the correct file, and then it begins the process of cutting.

After the cutting is finished, the Dark Horse team can take each piece off of the machine, apply its unique label, and sort the pieces according to the type of edgeband they are going to receive. We can start the edgebanding of those pieces while the next sheet is being cut.

Another member of the team can then begin to put the boxes together as soon as all of the parts for that assembly are made.

Flipping the process

My interest in programming and software has led me to approach decisions about technology investments in an unusual way. Many businesses invest in expensive machinery and then learn how to use the software that makes it run.

At Dark Horse, we’ve always gone in the opposite direction; to me, it doesn’t make much sense to have an expensive machine sitting idle in my shop while my team and I spend time wrapping our heads around how the software works.

So we buy the software first and learn it inside and out through tutorials or videos.

By the time a new machine is delivered, we’re ready to roll. This doesn’t mean we never have questions once we start using it; that’s a given. But those questions are easier to resolve quickly if you have a solid understanding of your software and machinery.

I believe this philosophy has been a major factor in our success. With this machine implementation, we were up and running at full speed as soon as the machine was integrated into our software, which was only one day after the machine installation was complete.

Two months in, we are completing projects that fully utilize our new technology in about one-third of the time we were spending before bringing the CNC on board.

~ Chris Dehmer

On Wednesday, July 17, Chris participated in a panel discussion titled “Taking the Leap to a Bigger Machine: What You Need to Know Before You Invest.” Chris and

On Wednesday, July 17, Chris participated in a panel discussion titled “Taking the Leap to a Bigger Machine: What You Need to Know Before You Invest.” Chris and

In December, I’m going forward with long overdue knee replacement surgery.

In December, I’m going forward with long overdue knee replacement surgery.

The International Woodworkers Fair (IWF) is coming to Atlanta in August, and Dark Horse is pleased to be a featured stop on a pre-IWF shop tour organized by the Cabinet Makers Association (CMA).

The International Woodworkers Fair (IWF) is coming to Atlanta in August, and Dark Horse is pleased to be a featured stop on a pre-IWF shop tour organized by the Cabinet Makers Association (CMA).