I recently had the eye-opening experience of seeing some high-end homes that had surprisingly low-end cabinetry. While many of the cabinets looked nice when you glanced at them with the doors shut, you only had to inspect them a bit more closely to figure out that the materials and construction were not exactly top-of-the-line.

Frankly, it was a shocker.

How did such shoddy work end up in such exclusive, expensive projects?

When you’re in a craft profession, this kind of thing can be frustrating.

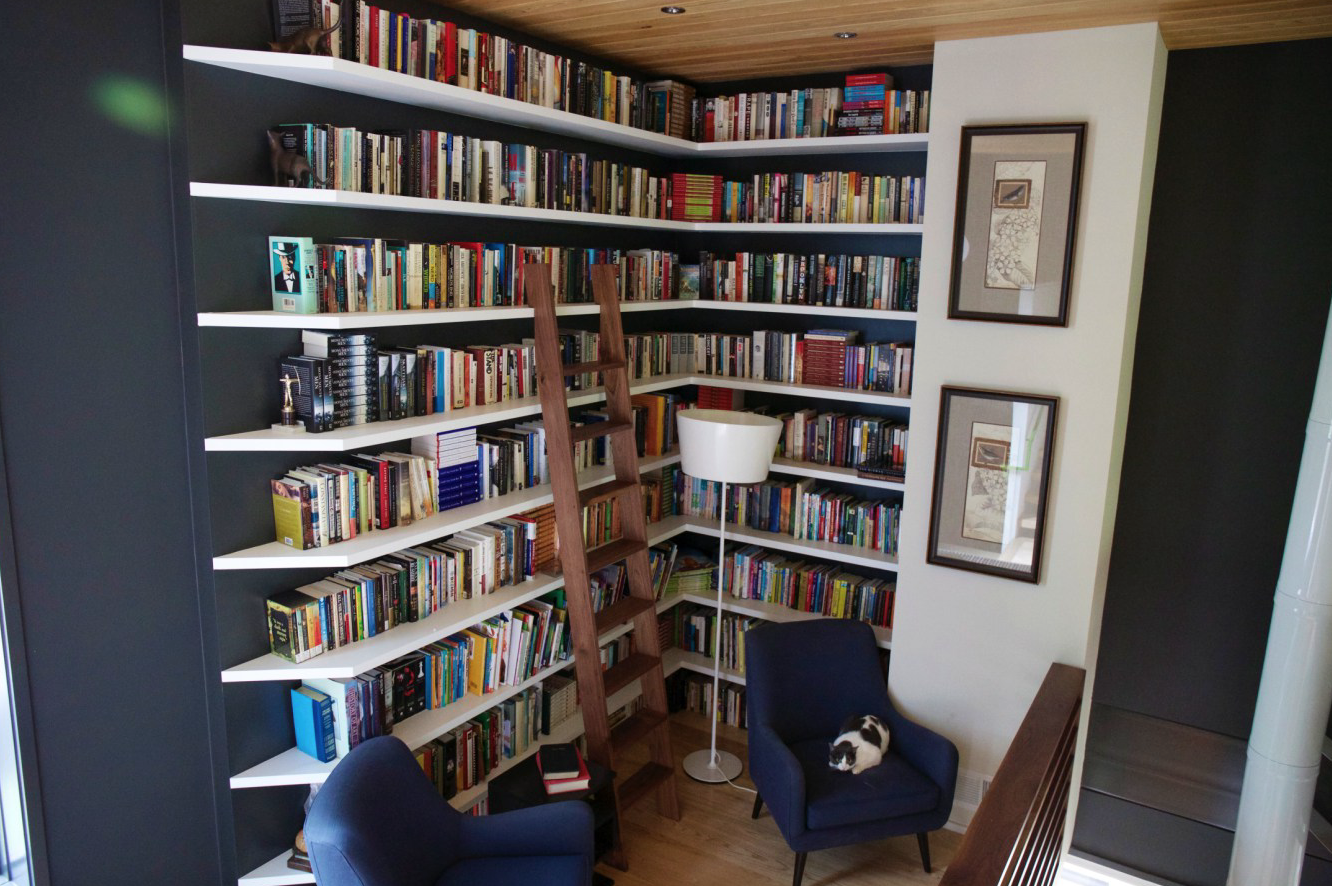

We’re grateful to have gained the trust of clients who have hired us to create their dream kitchens and other projects; this is the project we call “The Walnut House.”

Knowledge matters

Coming across this less-than-impressive work in otherwise well-crafted, big-budget homes made me stop and think about how these decisions are made.

Do the homeowners just not worry about the details that make the difference between a high-quality project and a shoddy one? Or do they not know?

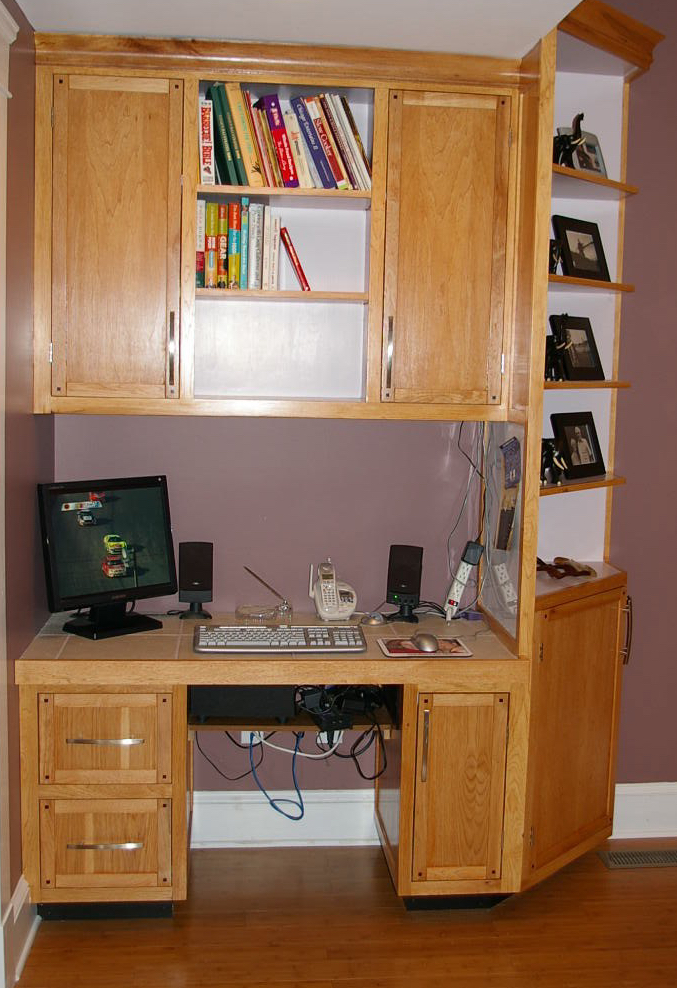

For those who are considering a remodel or new construction, I thought I’d pass along some insider perspective based on the Dark Horse approach to custom cabinetry.

First, it’s my experience that while clients know the big picture of what they want (style, color, etc.), they almost never tell you what they want when it comes to materials and construction.

For that reason (and many more), we have a spec sheet that we share with potential clients that outlines the type of materials we use. We’re careful to say, “This is what you’re getting.”

Our specs are identical 99 percent of the time; we never approach a potential job with the idea that we’ll customize our specs and use lower-quality, cheaper materials in order to give Dark Horse a better chance of winning a bid.

We’ve built our reputation on executing client projects the best way we know how, and in addition to the level of craftsmanship we offer, we make a point of seeking out the best products and materials available.

Here are a few examples:

- Every cabinet box we build is two-sided, pre-finished and US-sourced.Why US-sourced? Once, we tried cheaper Chinese import plywood for some shop projects; when we cut the material, it smelled funny, and the sawdust from the cut was blue. Consistency in thickness is more critical than ever since we incorporated a CNC into our production – we have to tell the machine how thick the material is so that the joints come out tight. Domestic plywood tends to be much flatter – I’m not sure why this is but my guess is that it has something to do with the imported plywood sitting on a ship during transport.

To give you an idea of the difference in materials, the domestic plywood we use costs $65-70 a sheet; some companies use particleboard that costs $18 per sheet (similar to what you see in IKEA furniture).

- We don’t use prefab drawers, and that makes a huge difference in both looks and function.

- We also use Zero Edge banding on our cabinetry, which is more heat- and moisture-resistant than typical edge treatments. But that advantage comes at a price – 80 cents per foot instead of 2 cents per foot for traditional hot glue edge-banding.

- We use soft-close doors, slides, etc. – in short, the best hardware we can buy. It costs a little more, but it’s worth it. (There’s a lot of cheap, shoddy hardware out there.)

Here’s an in-process photo showing the kind of 3/4-inch prefinished plywood cabinet box construction that goes into all of our projects; this happens to be my own kitchen, which my wife and I decided to renovate last year. (There’s no top because this is a sink cabinet.)

What’s the lesson you can take away from this insider view?

You get what you pay for.

A company with a solid reputation and happy customers obviously excels at the craft of cabinet-making, but that company also begins with high-quality materials, and those materials cost more. (I have yet to find a magical source of stellar materials at bargain basement prices, but if you have any leads, I’d love to hear about them.)

Our Golden Rule

Some companies have the advantage of a showroom where clients can see examples of their work; that would be a great way to show our clients what quality materials and craftsmanship look like, but a showroom is not an option for Dark Horse.

So instead, we just try to emphasize to clients what we choose to use in our work and why we choose it.

And the “why” is simple – it’s the way I would want it done in my house. If I wouldn’t put it in mine, I won’t put it in yours.

~ Chris Dehmer

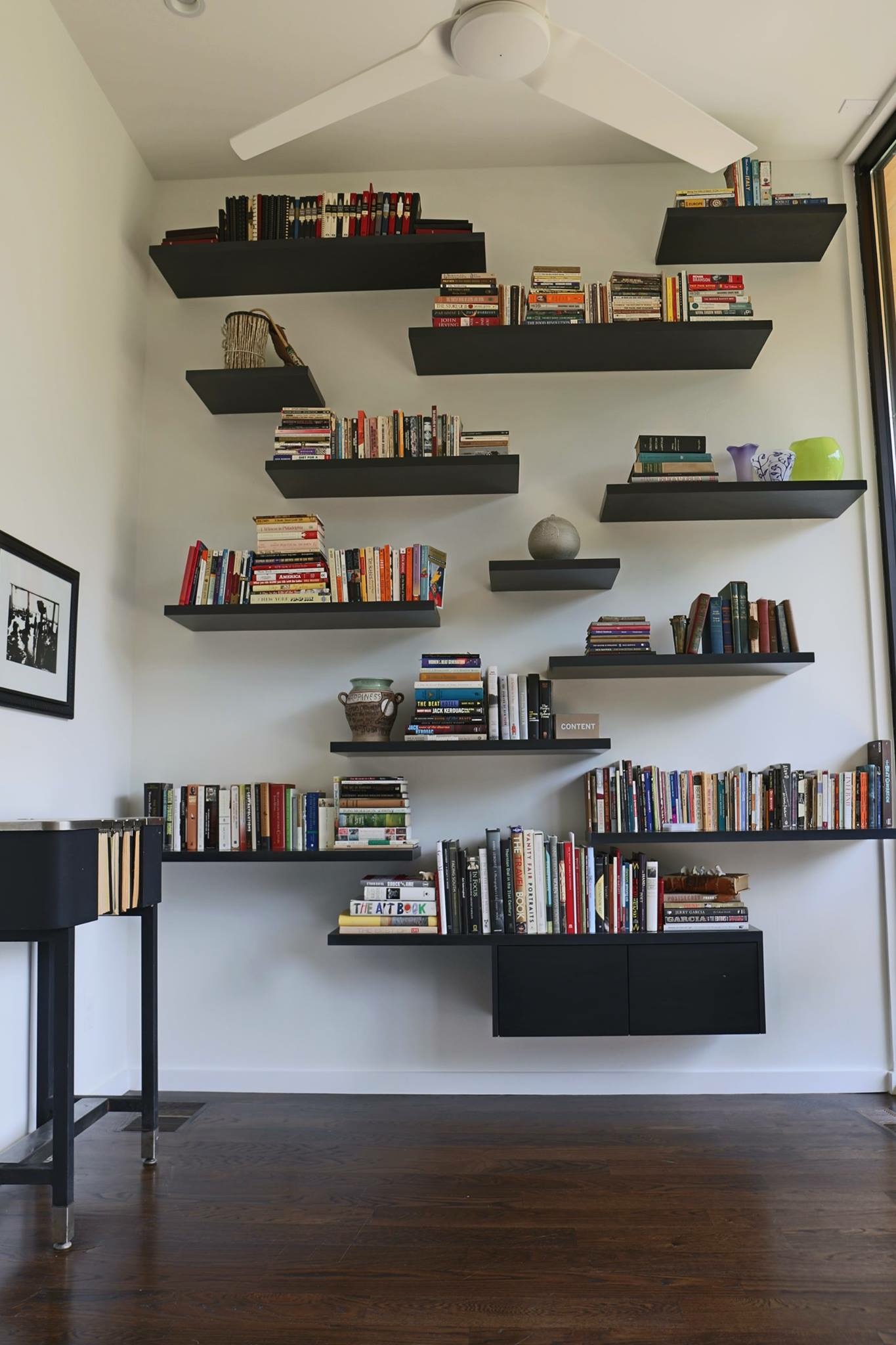

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.

For most of our projects, we create cabinetry for multiple rooms in a home, and we end up with extensive photos of the final “product” that we share in our gallery.