We have big news that our friends in the furniture and wood-working world may understand best: We’ve acquired the technology to produce cabinetry and furniture components with seamless edges.

Zero-Edge Technology, as it’s usually called, is a game-changer for our company and the industry as a whole.

Why is it such a big deal?

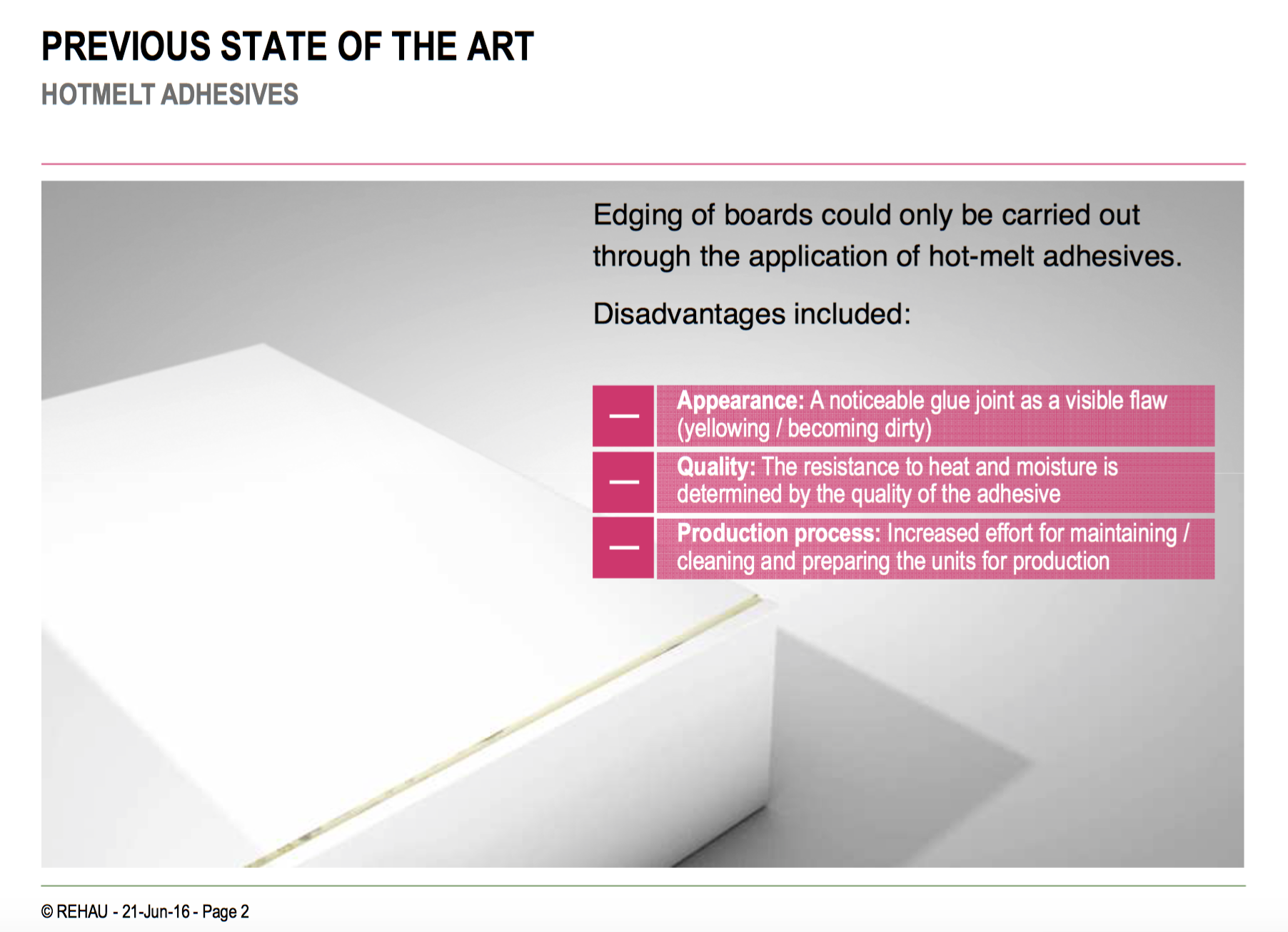

In short, because it’s always a challenge to add edge-banding to panels without a noticeable seam that is prone to fail eventually. Zero-Edge banding is more heat- and moisture-resistant than typical edge treatments.

REHAU, a polymer company, agreed to let us share these images from a presentation they created:

One of the trends we’re seeing in our work is the increasing demand for high-gloss cabinetry, and to create these cabinets, you have to have zero-edge capability.

With gloss acrylic, you can’t have a glue line, so the zero-edge machine melts the back of the edge and trims it off so your creation appears to have always been a single component.

If you happen to be fascinated by technology, design and woodworking/cabinetry, and getting into the nitty-gritty of this sort of thing interests you, the folks at Woodworking Canada have written a great article about the future of Zero-Edge technology. Here are a few of the highlights/excerpts from the article:

“If what’s happening in Europe is any indication, and it usually is, then the demand for zero edge will increase dramatically in North America and Canada, and most experts agree that in as little as two to five years, invisible edges will make up a significant portion of our market as well.” ~ Murat Dugan, president of IMA Canada Corp, a pioneer in edge-banding

How does it work?

“Using a co-extruded, active layer that is colour-matched – rather than applying hot-melt glue as is the norm in traditional edge-banders – the new system creates a zero edge or invisible glue line that is difficult to distinguish from one produced using a laser unit.”

What are the advantages?

“Not only is zero-edge aesthetically pleasing, but it also makes for stronger and longer-lasting edges and offers anti-bacterial benefits that make it a great solution for restaurants, health-care and similar public uses.”

And zero-edge is often necessary for “contemporary, slab or high-gloss cabinetry, which continues to grow in popularity.”

We love being ahead of the curve at Dark Horse – thanks to our new investment, we can produce the high-gloss acrylic cabinetry called for in our next two projects. The zero-edge machine also opens the door to commercial projects and will enable us to provide some services that shops and even homeowners in the region have not had access to until now.

Stay tuned to see what new territory Dark Horse heads into next!